Share to

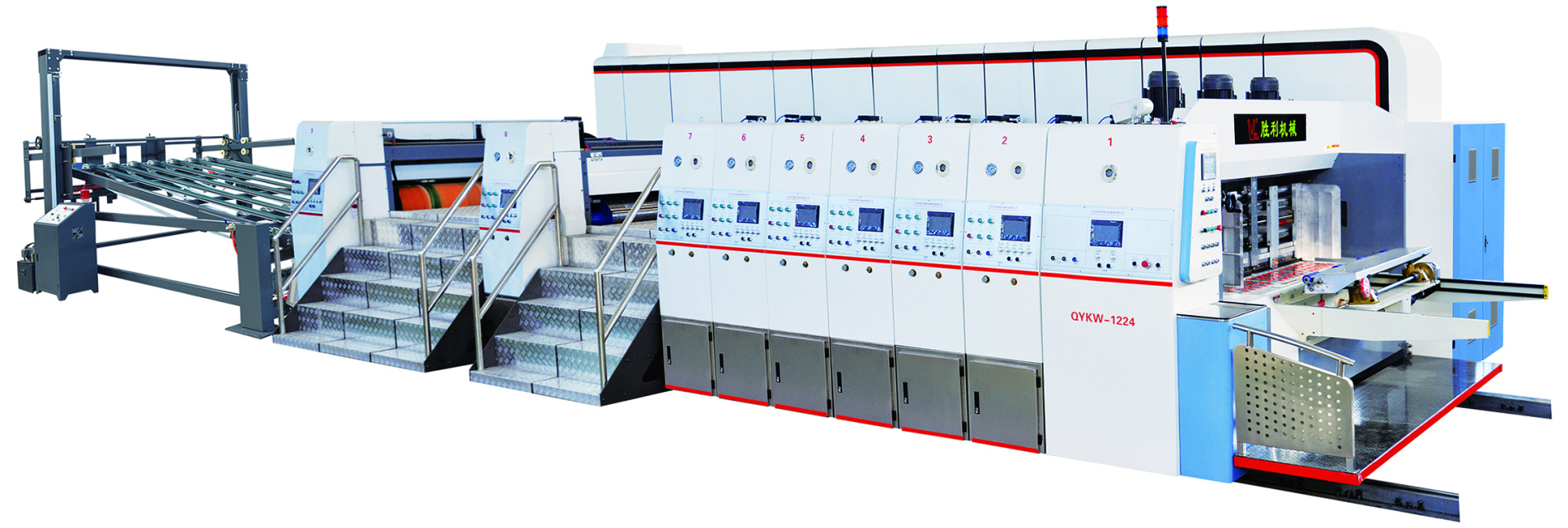

Fully Automatic Gluing Stitching Machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

Product features:

It is composed of vacuum paper feeding section, automatic folding section,automatic gluing section, automatic stitching section and automatic stackingcounting.

• Adapt corrugated board a.b.c. ab. corrugated, three, five layers of cardboard.*The whole computer control, simple operation, stable quality, speed to achieveeconomic benefits, greatly save manpower.:Machine can do three different job with nail, glue and first glue and then nail onefinish.

• Can automatically complete the paper folding, correction, nail box, paste box, countstacking output work.

• Bottomless lid box can also be nailed.

• Machine uses computer touch screen display operation and fault description.

• Can store orders, can remember 200 sets of order information.

• 3-5 minutes to complete the change order setting, can be mass production.

• Paper feeding part using vacuum belt paper feeding accuracy, not skew.

• The nail box works better, the nail distance is more accurate, the appearance isbeautiful. the paste carton has the characteristics of firm, smooth and clean mouth.

• The nail head and pat shaping part is operated by a servo motor with stable andaccurate nail spacing.

• The carton can be stapled after paste.

• Glue evenly without glue, easy to dry and clean.

• Spacing range:40-500 mm.

• Head speed: 600 nails/min. Take three nails as an example up to 70 tablets perminute.

• Pin angle: 45°.

• Single nail, double nail can be adjusted freely, applicable to standard 18 # nail wire

• Reduce manpower dependency and replace manual paste and nail-box operations

• When glue carton box need fewer people, faster, two people on paper, two peoplebundled, two people back and forth transport ,8 hours easy more than 100,000sheets.

• Suitable for export packaging,environmental protection packaging, such asbeverage boxes, beer boxes,convenience boxes, tile boxes and other high-gradesub-packaging cartons.

Machine parameter

| Specification | |

| Machine height | 1200mm |

| Machine length | 15000mm |

| Machine width | 3500mm |

| Machine weight | 6500kg |

| Gluing Speed | 120m/min |

| Stitching speed | 70 Pieces/min |

| Stitching distance | 30-100mm |

| Stitching number | 1-99 Stitches |

| Pressure requirements | 0.6Mpa |

| Total power | 15Kw |

| Powerconsumption | 8Kw/H |

| Scope of use of gluing box section | |

| Max length(A+B)×2 | 2600mm |

| Max size A | 800mm |

| Min size A | 200mm |

| Max size B | 500mm |

| Min size B | 160mm |

| Min length(A+B)×2 | 720mm |

| Max width(C+D+C) | 1100mm |

| Min width(C+D+C) | 300mm |

| Height of feeder | 500mm |

| Scope of use of gluing box section | |

| Model | QZD2600B |

| Size A(mm) | 130-800 |

| Size B(mm) | 80-500 |

| Size C+D+C(mm) | 170-1100 |

| Size A+B+A+B(mm) | 420-2600 |

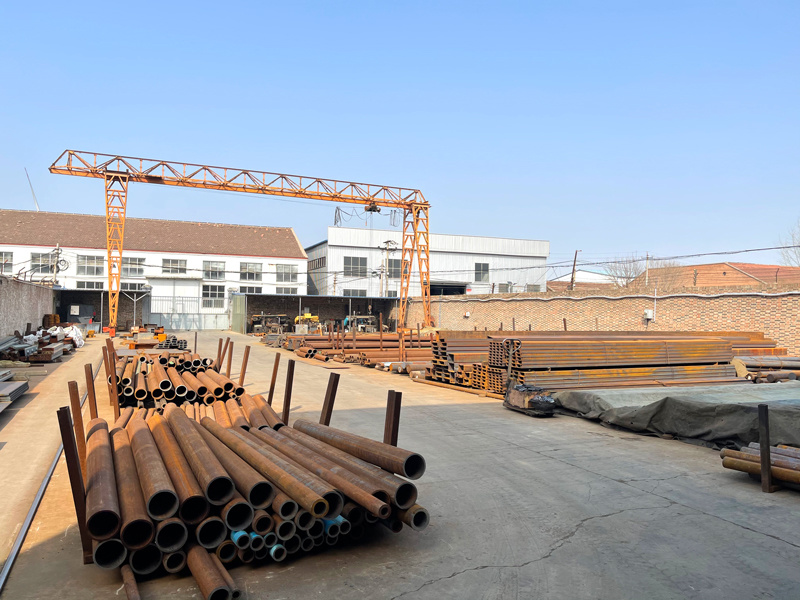

Our Advantages:

Professional cardboard box machinery manufacturer

Our main units include pressure corner slicers, slitting machines, 3, 5 and 7-ply corrugated cardboard production lines, automatic and chained rotary die-cutters and rolling lines, single face corrugated cardboard machines, paper rolling lines, pasting machines, platform grinder slicers, stitching machines and other related products.

■ Superior geographical location

■ Advanced equipment and excellent product quality

■ Our products are exported overseas

Company exhibition:

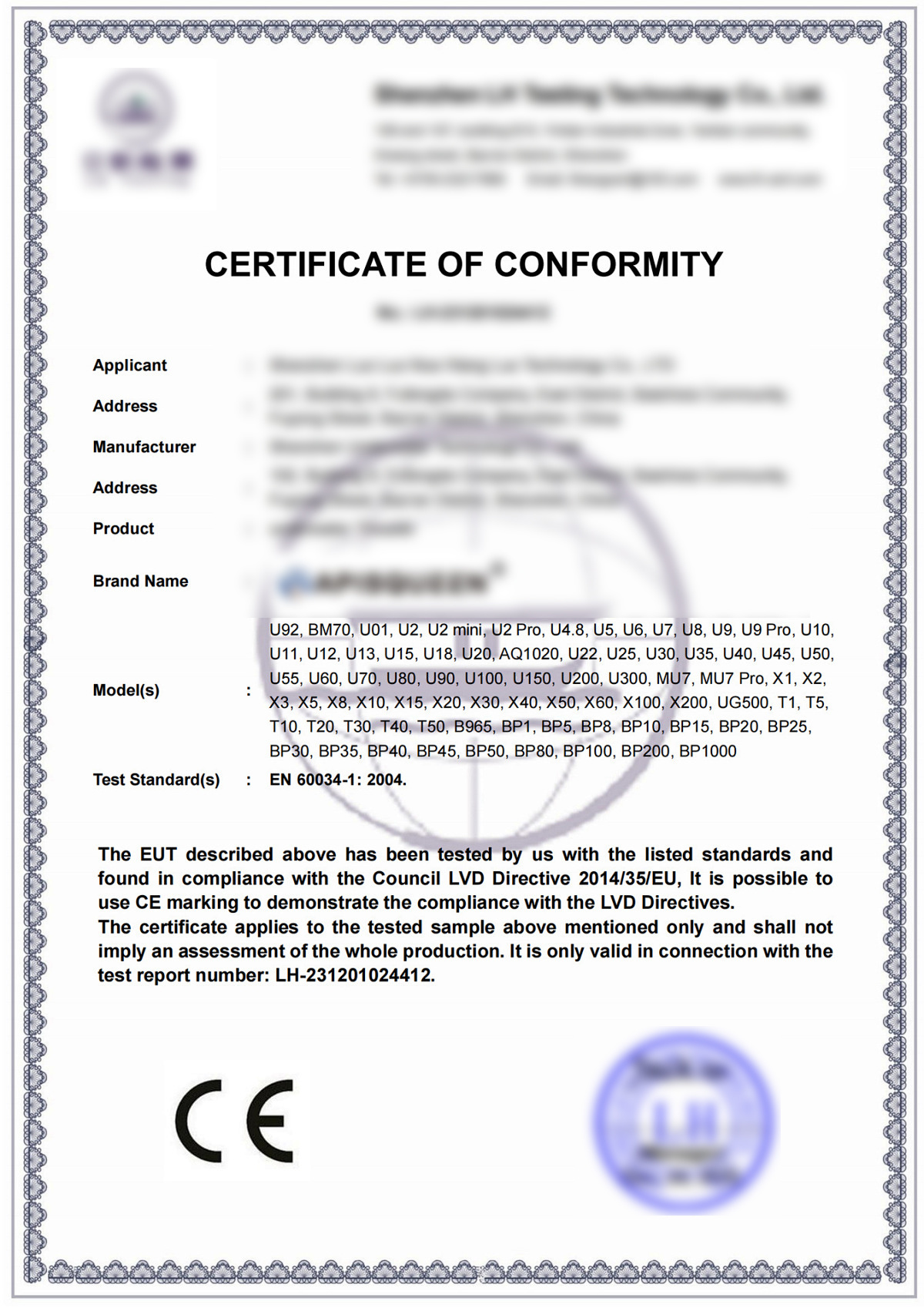

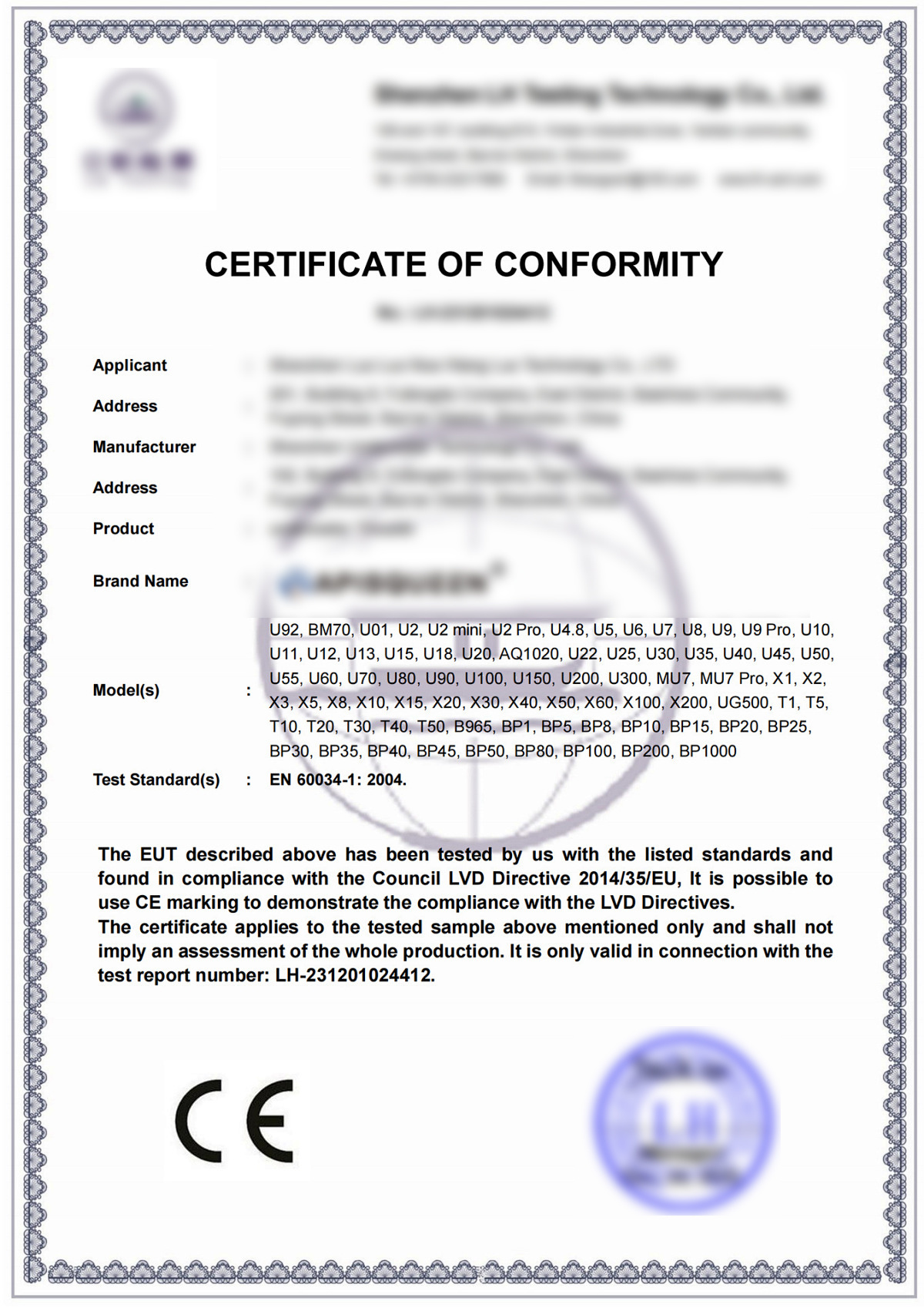

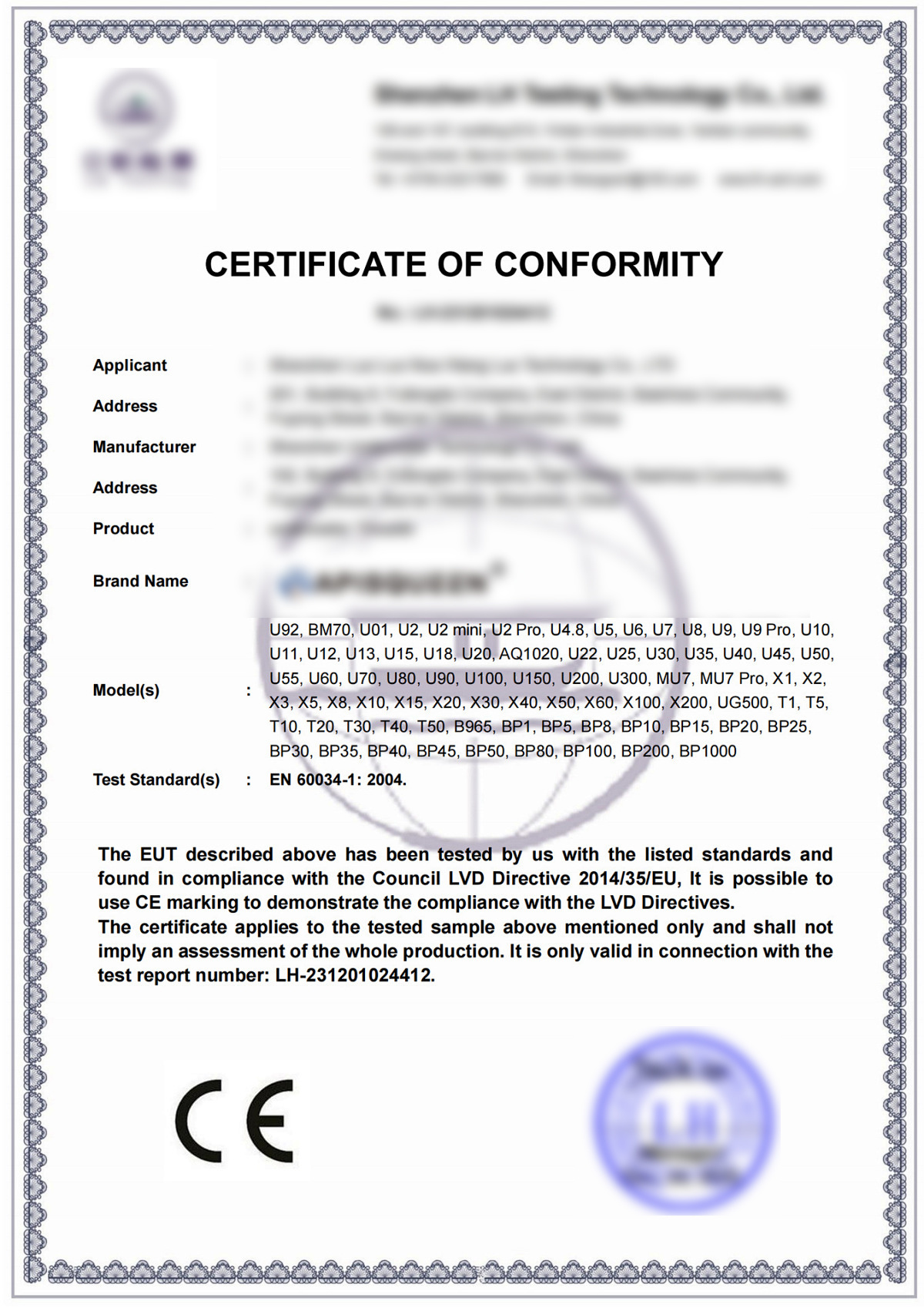

QUALIFICATION:

Fully Automatic Gluing Stitching Machine

Still deciding? Get samples first, Contact US !

Products Category

Keywords

Related Products

Inquire Now

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!