Share to

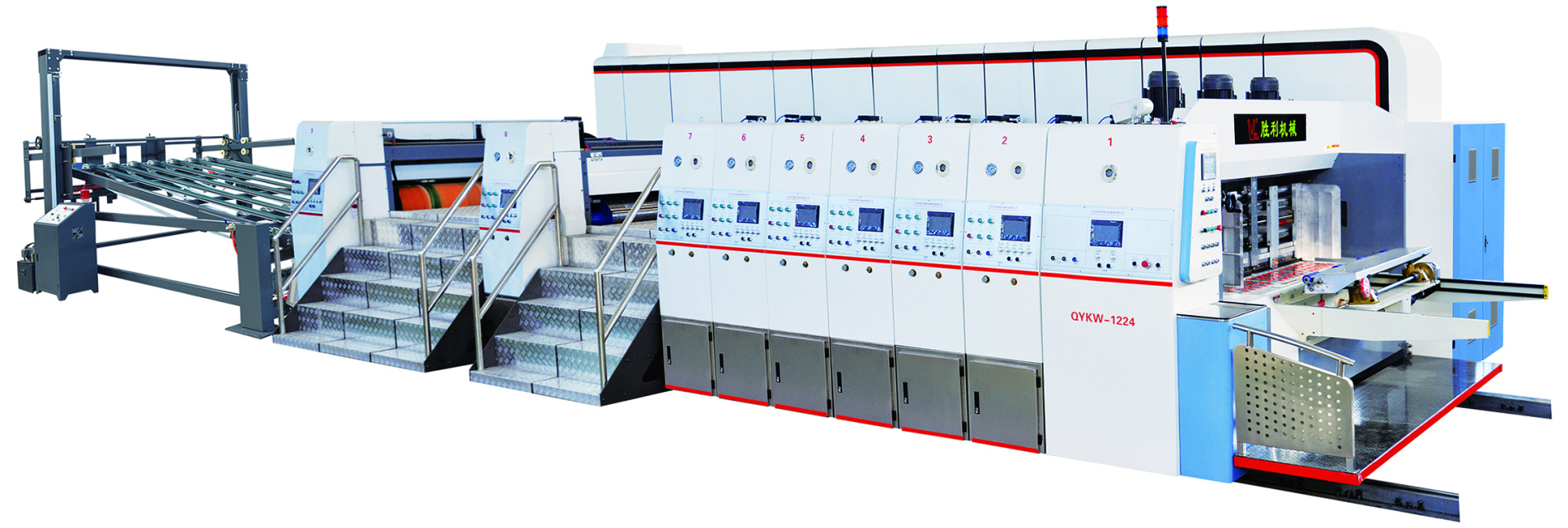

SL series high-speed printing sticky box strapping linkage line

Still deciding? Get samples first, Contact US !

View similar products

Tag list

Product features:

Function,characteristics and configuration:

Servo printing fold gluing bundling linkage line achieve CNC computer numerical control linkage operating system,each unit servo drive independently,accurate synchronization effect,speed is stable and reliable;Possess the order management function;Accomplish the carton printing,fold gluing,bundling in line with high efficiency production.Ordinary carton box printing,the highest design speed of up to 300pcs/min;Coated paperboard printing can reach 80-120 pcs/min.Design concept according to advanced European technology,and through the European CE Ceritification,is the best choice for improving the production efficiency,reducing the manpower cost,automated corrugated box production,printing and forming process.

Machine Details:

Machine parameter:

|

Parameter name |

Unit |

Specification |

|

|

SYKW-920 |

SYKW-924 |

||

|

Design speed |

Pcs/min |

350 |

300 |

|

Maximum size of feeding pape |

mm |

900×2000 |

900×240 |

|

Minimum size of feeding paper |

mm |

280×600 |

280×600 |

|

Feeding paper by partition |

mm |

1100×2000 |

100×2400 |

|

Maximum size of printing area |

mm |

900×1960 |

900×2360 |

|

Precision of printing |

mm |

±0.2 |

±0.2 |

|

Thickness of standard printing planl |

mm |

7 |

|

|

Thickness of printing paperboard |

mm |

2-11 |

2-1- |

|

Slotting precisior |

mm |

±1 |

±1 |

|

Minimum grooving space |

mm |

130 |

130 |

|

Maximum depth of slotting |

mm |

260 |

260 |

|

Printing roller axial regulating |

mm |

±10 |

±10 |

|

Die cutting preci sio |

mm |

±1 |

±1 |

|

Die cuting knife roller axial regulating |

mm |

±10 |

±10 |

Machine parameter:

SYKW Series of Servo Printing Fold Gluing Bundling Linkage Line - Prefeeder

1. Design security accord with the European CE safety standards and strive to humanized operation.

2.Adopt lead edge feeding paper technology with high precision.

3. Configuration with electrostatic brush and ion wind saber eliminate cardboard electrostatic

4. Adopt America SUN company color master single doctor blade, the printing is more clear and perfect.

5. Phase adjustment adopt servo control to make sure rapid response and accurate adjustment.

6. Vacuum transfer paperboard system, wind power balance design makes running accuracy higher,feeder svstem can be fexible matching roller feedingand hot air drying system function, or achieve roler feeding and vacuum transfer double function, saving energy and reducing consumption.

7.Die-cutting anvil roller adopt sinale servo more independent drive.realizes speed difference compensation between rubber cushion and templatemanufacturing error compensation

8. Die-cuting roler automaticaly eliminate the adiusing mechanism gap and die cuting vibration, improve the service life of the equipment.

9. Drving system, which has two kinds of infrared and uitraviolet rav, can respecively dving water-based ink, ight ol and UV lioht oll. Temperature controsystem to ensure the safety of production. According to the board width automatically adjust scope of dry, to save energy.

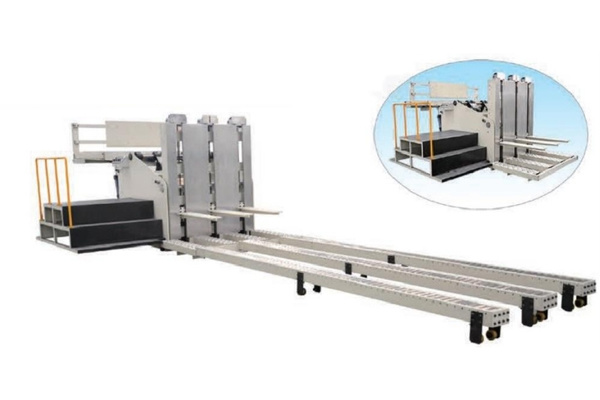

SYKW Series of Servo Printing Fold Gluing Bundling Linkage Line - Prefeeder

1.Both side positioning baffle, can be adjusted according to different size of the cardboard,specification with electric adjustment.

2.Operation control is simple and convenient.

3.Supporting paperboard roller way can connect cardboard logistics delivery system.

4.Horizontal conveyor belt automatic control with hydraulic motor drive.

5.Traveling mechanism can connect with printing machine synchronously.

6.Automatic control paperboard transport with PLC.

SYKW Series of Servo Printing Fold Gluing Bundling Linkage Line —— Fold Gluing Machine

1. Folding unit front part up and down belt synchronous drive, rear part adopt vacuumabsorption feeding paperboard, transfer paperboard smoothly.

2. Both left and right folding belt adopts independent servo motor drive, it can adjust thefolding running speed difference accurately, eliminate the scissors error.

3. Cardboard transport adopt vacuum adsorption orientation.

4. Molding wheel auxiliary folding type, in the process of cardboard folding line to proceedthe second forming to stabilize the carton size.

5. Servo speed difference compensation to decrease the glue phenomenon not neat, seryocontrol by batches to achieve partial stack at high speed.

6. Eject glue type to improve adhesion reliability and to avoid the glue pollution to carton andconveyor belt.

7.Automatically achieve 10~ 25 pcs automatic counting, partial bundling and transportation.

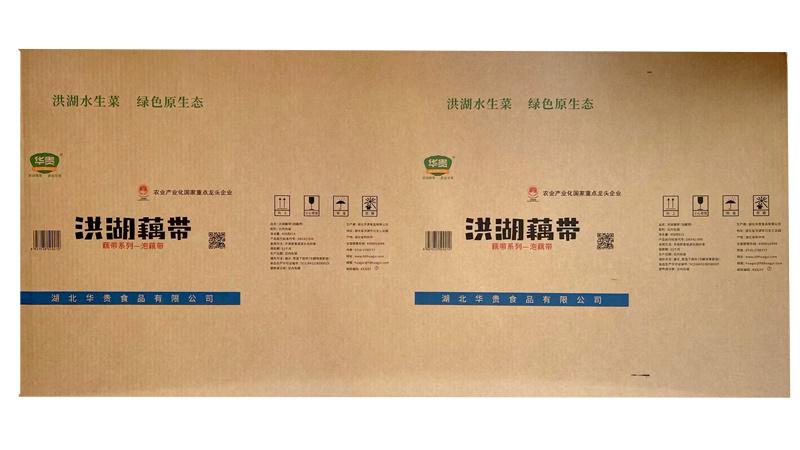

Finished Product:

Our Advantages:

Professional cardboard box machinery manufacturer

Our main units include pressure corner slicers, slitting machines, 3, 5 and 7-ply corrugated cardboard production lines, automatic and chained rotary die-cutters and rolling lines, single face corrugated cardboard machines, paper rolling lines, pasting machines, platform grinder slicers, stitching machines and other related products.

■ Superior geographical location

■ Advanced equipment and excellent product quality

■ Our products are exported overseas

Company exhibition:

QUALIFICATION:

SL series high-speed printing sticky box strapping linkage line

Still deciding? Get samples first, Contact US !

Products Category

Keywords

Related Products

Inquire Now

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!