Share to

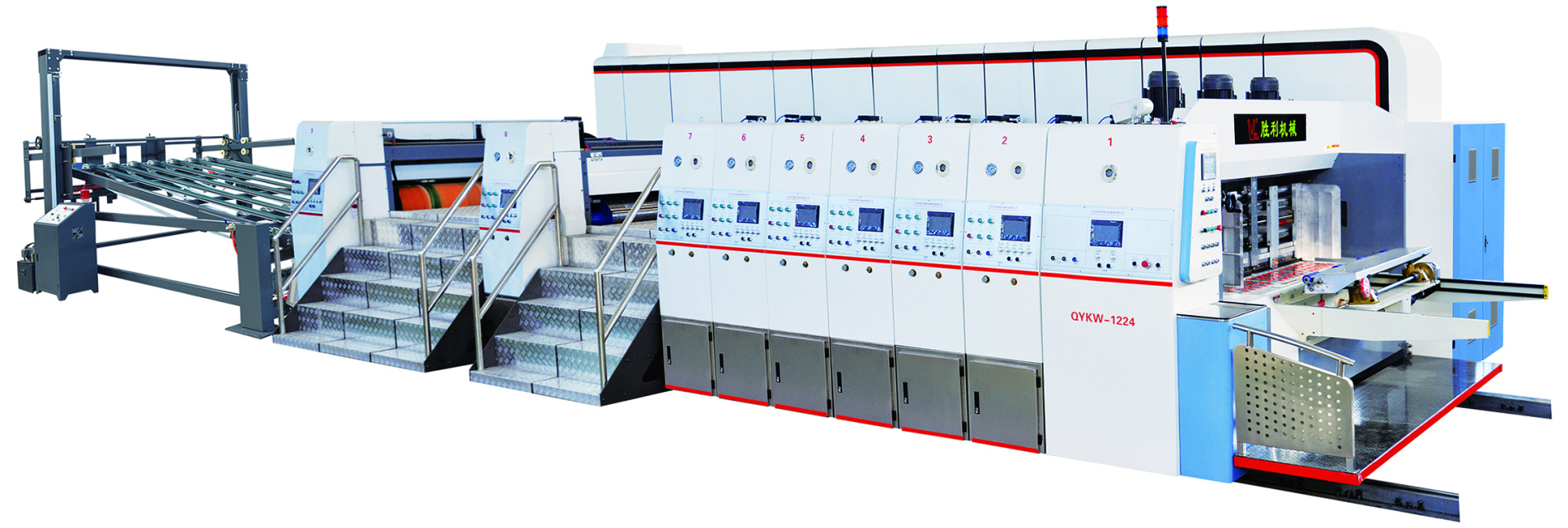

YKW/GYK Series of High Speed Flexo Ink Corrugated Paperboard Printing Slotting Die Cutting Machine

Still deciding? Get samples first, Contact US !

View similar products

Tag list

Product Feature:

1. All the main electric appliances of the whole machine adopt the product ofSchneider made in France.

2. Adopt wheel lead-edge feeder system.

3. Adopt helical gear driving,the gears are made from high frequency quenchingand after grinding processing.

4. The gears adopt shower type circular lubricating and with oil balance function.

5. Adopt inverter motor to drive and adjust the speed by frequency conversionwithin the certain scope.

6. Printing slotting and die cutting electric phase adjusting mechanism.Planettype gear structure 360 degrees.(lt can be adjusted while revolving andstopping).resolution response rate is 0.2mm.

7. Adopting the mould piece designing.The multi-color printing machines can becombined and linked in any way.

8. Each unit adopt touch screen control.

Product parameter:

| Serial | Name ofparameter | Unit | Specification | ||||||

| YKW1370×2200 | YKW1370×2500 | YKW1370×2800 | GYK1700×2500 | GYK1700×3000 | GYK1700×3500 | ||||

| 1 | Width of inside machine | mm | 2400 | 2700 | 3000 | 2700 | 3200 | 3700 | |

| 2 | Design speed | pieces/ min | 200 | 200 | 200 | 160 | 160 | 160 | |

| 3 | Max.sizeof feeding paper | Manualslotting | mm | 1300×2100 | 1300×2400 | 1300×2700 | 1630×2400 | 1630×2900 | 1630×3400 |

| Computer slotting(knite same direction) | mm | 1300×1900 | 1300×2200 | 1300×2500 | 1630×2200 | 1630×2700 | 1630×3200 | ||

| Computerslotting(knile opposite direction) | mm | 1300×2100 | 1300×2400 | 1300×2700 | 1630×2400 | 1630×2900 | 1600×3400 | ||

| 4 | Minimumsize of feeding paper | mm | 400×700 | 400×700 | 400×700 | 500×700 | 500×700 | 500×700 | |

| 5 | Feeding paper by partition | mm | 1600×2100 | 1600×2400 | 1600×2700 | 2000×2400 | 2000×2900 | 2000x3400 | |

| 6 | Maximum printing area | mm | 1300×2040 | 1300×2340 | 1300×2640 | 1630×2340 | 1630×2840 | 1630×3340 | |

| 7 | Precision ofprocessprinting (double/three/four color) | mm | ±0.5/±0.75/±1.0 | ±0.5/±0.75/±1.0 | ±0.5/±0.75/±1.0 | ±0.5/±0.75/±1.0 | ±0.5/±0.75/±1.0 | ±0.5/±0.75/±1.0 | |

| 8 | Thicknessof standard printing plank | mm | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | |

| 9 | Thickness of printing paperboard | mm | 2-11 | 2-11 | 2-11 | 2-11 | 2-11 | 2-11 | |

| 10 | Minimum grooving space | Manual slotting | mm | 190×50×190×50 | 190×50×190×50 | 190×50×190×50 | 210×60×210×60 | 210×60×210×60 | 210×60×210×60 |

| Computer lateral movement | mm | 170×170×170×170 | 170×170×170×170 | 170×170×170×170 | 180×180×180×180 | 180×180×180×180 | 180×180×180×180 | ||

| Computer lateral movement | mm | 280×70×280×70(180) | 280×70×280×70(180) | 280×70×280×70(180) | 280×80×280×80(190) | 280×80×280×80(190) | 280×80×280×80(190) | ||

| 11 | Maximum depth of slot | mm | 340 | 340 | 340 | 410 | 410 | 410 | |

| 12 | Die cut slottingthickness | mm | 3-8 | 3-8 | 3-8 | 3-8 | 3-8 | 3-8 | |

| 13 | Maximum die-cut size | mm | 1300x2100 | 1300x2400 | 1300x2700 | 1630×2400 | 1630×2900 | 一一 | |

Product details:

Function of Feeding Department

1. Paperboard feeding adopt leading edge, paperboard feeding is more accurate.

2. lt can send the paperboard continuously or by partition equipped (with counting device ).

3. Electric controing the clutch ofthe machine plaform and instaled alams in order to assure the safe of the operating personnel whie the bell ings constaintly during marching

4. The electrical machinery ofthe main engine slarts the protective device.lfthe machine has not been locked.the main engine can not start revolving.

5. The separaing electrical machinery starts the protective device.(lfthe machine has been locked you can not start the separating electrical machinery.)

6. lt can adiusting feeding paper running ,relieve feeding glue roller's preesure .

7. dust collecting plant, brushes and the air blower can clear the dust and the paper scrap of the paperboard surface

8. Back baffle、 left and right baffle adopt electric controll.

9.With side pusher function.

Function of Printing Department

1. The printing roller and trace pressing roller adopt High quality steel material. To grind the surface and dothe hard chrome plating.

2. All drive roller adopt dynamic balance correction, so the revolving is steady.

3. To load and unload the printing plating and step on the switch. Electric controlling the positive and negativerevolving.

4. With ink shortage alarm function.

5.Phase-adjusting mechanism, planet type gear structure, electric digital control.

6. Printing phase fixed device, pneumatic brakes. While the machine separates or the phase is adjustingthe brakes can restrict the revolving of the machine platform and keep the fixed point of the original aearsposition.

7.Rubber roller:The surface of the roller is steel pipe which is packed by the wear-resisting rubber. Adoptingmedium and high special grinding the rubber roller has effective ink-spreading optional doctor blade system.

8. The oil roller adopts high precision hard chrome plating net-grain roller.

9. Installed with ink roller rotation electrical machinery to the main engine's drying up while its stopping

10.The lateral movement of the plate roller adopt electric adjustment.

Function of Slotting Department

1. Slotting phase adjusting mechanism, planet type gear structure, electric digital control.

2. Opening slot, pressing line, distance putting board type, four axles must be adjusted by handsynchronously. Chest height must be adjusted by hand synchronously.

3. The width of the slotting knife is 7.0mm and of alloy steel material. Under heat treatment blade grindinghackles and double blades side repairing knife are very sharp and long using life.

4. The part of slotting can install the punches and buttons beating equipments.

5.Optional four knives mould die cutting unit.

6.Optional computer PLC to adjust the carton size.

Function of Rotary Die Cutting Department

1. The cushion roller adopts mechanical camdrum portable structure (40mm).

2. The gap between the cushion roller and the cutter mould roller adopts electrical adjustmentWhen stopping feeding paper, the soft roller will rise automatically; When working,the sofroller will return to the working position.

3. Adopt compentating system.No matter how much the cushion diameter changes,the speed of the cushion compentate and follow automatically, without adjustment by man.

4. With restoration for cushion after wear and tear.Keeping the surface of the cushion smooth6.Optional free version slotting function.

5. Optional free version slotting function.

Hydraulic Stacker

1. Bin arm using pneumatic operation, manual control.

2. Bedtable lifting, hydraulic station double hydraulic cylinder drive, to ensure the safety of operators.

3. Stacking, using a flat wrinkles climbing belt and steel clamping device, so that the stacking orderand tidy.

4. Hold paper feeder can be adjusted to hold the opening width, with a batch accumulation function.

5. The use of side shoot baffles to ensure more orderly stacked cardboard.

6. Electric enforce the use of PLC programming control, independent of the operating electric box.

7.Optional vibration stripping and lateral waste function.

8.Stacker height: 1600mm.

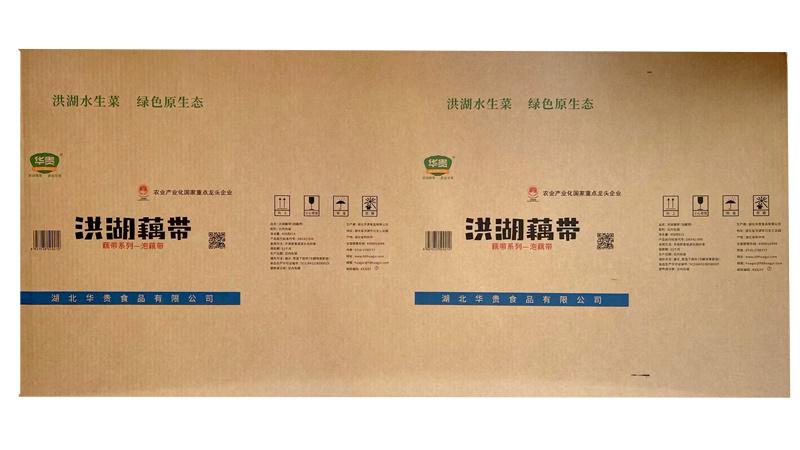

Finished Product:

Our Advantages:

Professional cardboard box machinery manufacturer

Our main units include pressure corner slicers, slitting machines, 3, 5 and 7-ply corrugated cardboard production lines, automatic and chained rotary die-cutters and rolling lines, single face corrugated cardboard machines, paper rolling lines, pasting machines, platform grinder slicers, stitching machines and other related products.

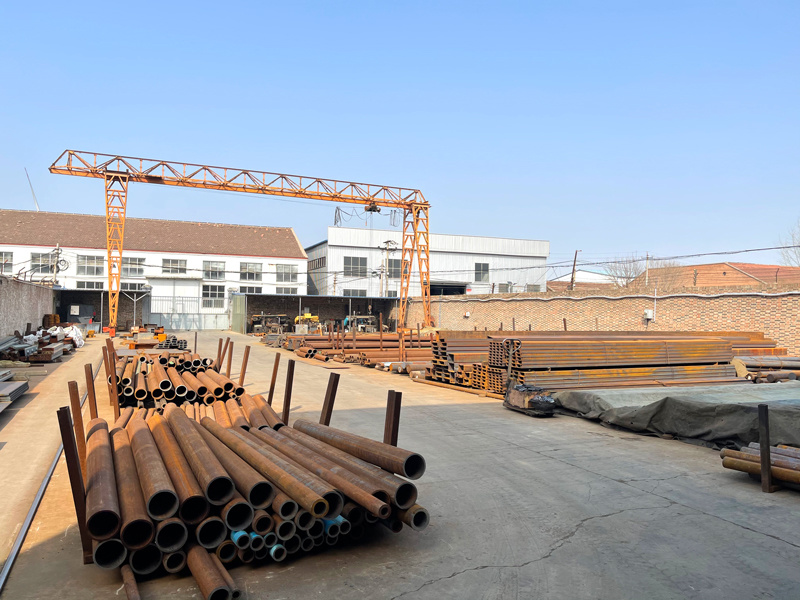

■ Superior geographical location

■ Advanced equipment and excellent product quality

■ Our products are exported overseas

Company exhibition:

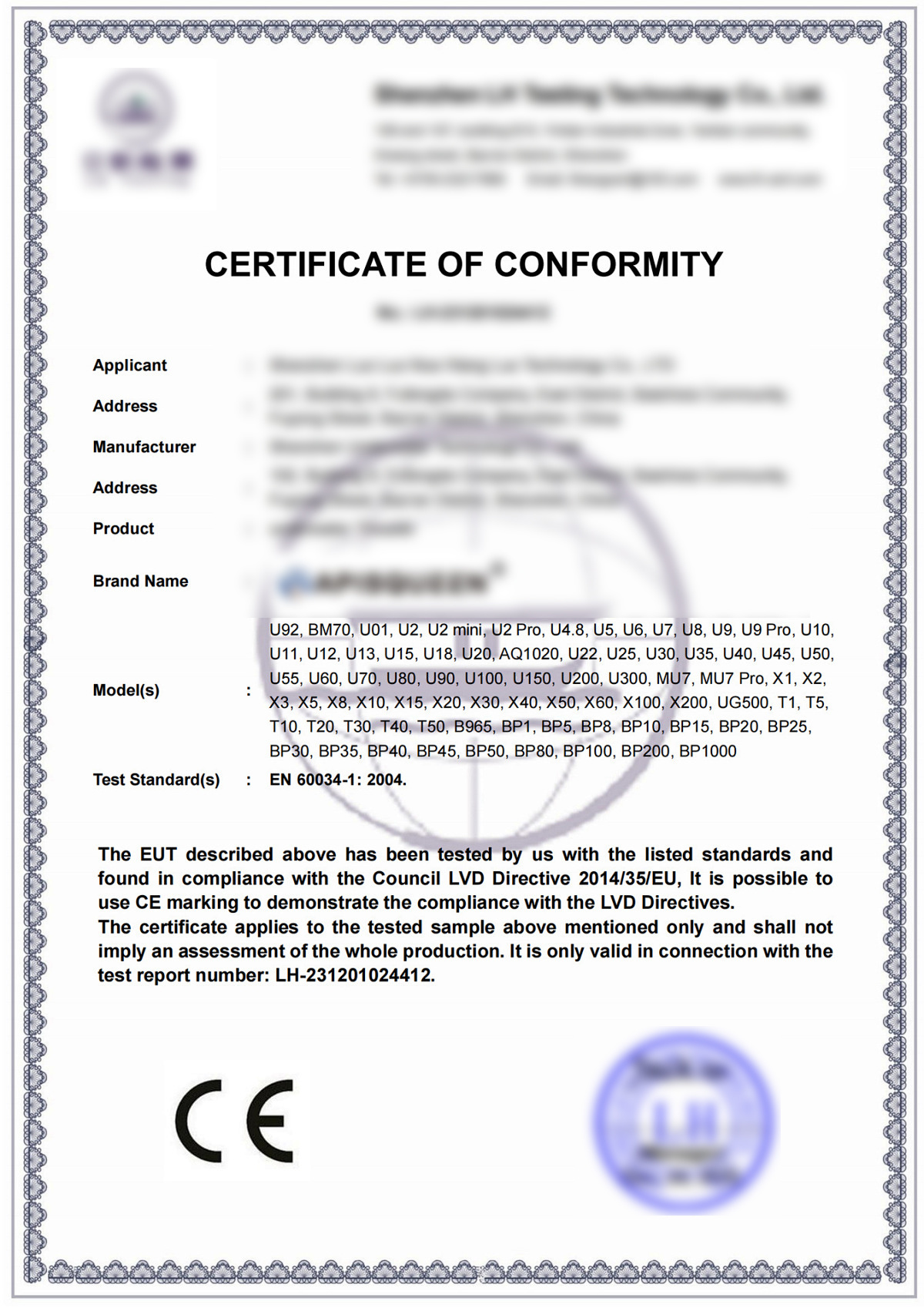

QUALIFICATION:

YKW/GYK Series of High Speed Flexo Ink Corrugated Paperboard Printing Slotting Die Cutting Machine

Still deciding? Get samples first, Contact US !

Products Category

Keywords

Related Products

Inquire Now

If you are interested in our products, please leave your email and we will contact you as soon as possible. Thank you!