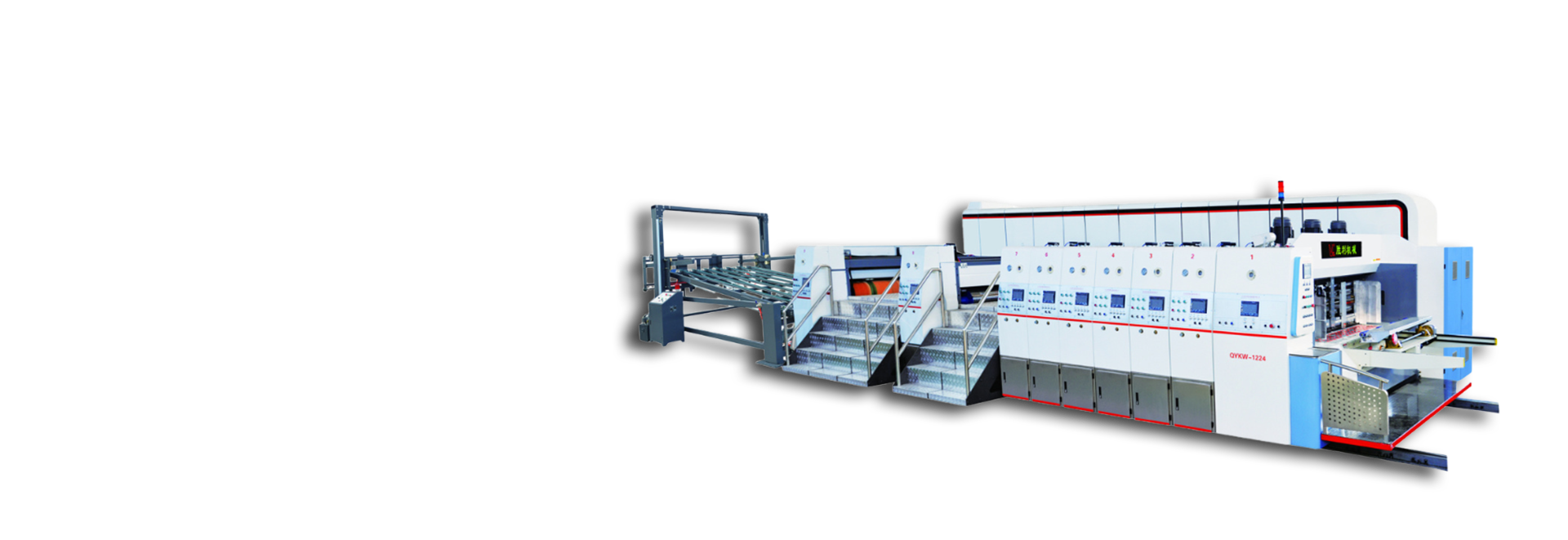

Vegetable box flexographic printing machine

Pubdate:

2025-04-15

Vegetable box flexographic printing machine is a highly efficient printing equipment specially designed for the printing needs of vegetable boxes.

1. Printing quality

High definition

Adopting advanced flexographic printing technology, patterns and texts can be accurately printed on vegetable boxes. Whether it is complex vegetable patterns, brand logos or text content such as nutritional instructions, they can be clearly presented to ensure the high quality of printing effects, which helps to improve the beauty and recognition of vegetable boxes.

Bright colors

The printing machine performs excellently in color management. It can accurately mix and print a variety of bright colors, making the patterns on the vegetable boxes full and vivid, and can quickly attract consumers' attention among many products, which has a positive effect on the sales of vegetables.

2. Production efficiency

High-speed printing

The Vegetable box flexographic printing machine has the ability to print quickly and can complete the printing tasks of a large number of vegetable boxes in a short time. This is crucial to meet the large-scale production needs of vegetable packaging companies, and can effectively improve production efficiency and reduce production costs.

Stable operation

The mechanical structure of the equipment is reasonably designed, and the coordination between the various components is good. During long-term operation, it can maintain a stable working state, reduce downtime and ensure the continuity of production.

3. Environmental protection characteristics

Environmentally friendly ink

Adapted to environmentally friendly flexographic printing inks, these inks have low volatile organic compound (VOC) emissions while ensuring printing quality, meet modern environmental protection requirements, reduce pollution to the environment, and ensure the safety of vegetables during storage and transportation.

Material adaptability

The vegetable box flexographic printing machine has good adaptability to different types of vegetable box corrugated cardboard materials. Whether it is thick cardboard or thin cardboard, it can perform high-quality printing and reduce material waste, which further reflects its environmental protection and economy.

4. Operation and maintenance

Easy operation

The operation interface is simple and intuitive, and the operator can master the operation method after simple training. Printing parameters such as printing speed and color concentration can be easily adjusted.

Easy maintenance

The structure of the vegetable box flexographic printing machine is convenient for daily maintenance and maintenance. Key components are easy to check and replace, which helps to extend the service life of the equipment and reduce the equipment maintenance cost of the enterprise.

Recommended Reading

quality Automatic corrugated carton making line

In today's booming packaging industry, a high-performance Automatic corrugated carton making line is crucial for businesses to improve production efficiency and reduce costs

The Evolution and Benefits of Corrugated Cardboard Digital Printer Machines

The corrugated cardboard digital printer machine represents a significant innovation in the realm of printing technology, particularly for those involved in the manufacturing and processing sectors. These machines are designed to print directly onto corrugated cardboard, which is widely used for packaging and displaying products. The evolution of digital printing technology has transformed traditi

Maximize Production with Advanced Corrugated Box Die Cutting Machines

Maximize Production with Advanced Corrugated Box Die Cutting Machines Table of Contents 1. Introduction to Corrugated Box Die Cutting Machines 2. Importance of Die Cutting in Packaging 3. Key Benefits of Advanced Die Cutting Machines 4. Essential Features of Modern Die Cutting Machines 5. Technological Advancements in Die Cutting 6. How to Choose the Right Die Cutting Mach

Innovative Corrugated Cardboard Production Line: Enhancing Efficiency and Quality

The corrugated cardboard production line is designed to produce corrugated cardboard sheets, which are critical in various packaging applications due to their lightweight, strength, and recyclable characteristics. The production process generally involves several key stages, including paperboard preparation, corrugating, lamination, and cutting. Each stage is crucial for ensuring the final product

Innovative Solutions: Features of High-Speed Corrugated Cardboard Box Press

Innovative Solutions: Features of High-Speed Corrugated Cardboard Box Press Table of Contents 1. Introduction to High-Speed Corrugated Cardboard Box Presses 2. The Significance of High-Speed Press Technology 3. Key Features of High-Speed Corrugated Cardboard Box Presses 3.1 Automation and Efficiency 3.2 Energy Efficiency 3.3 Quality Control

Revolutionizing Packaging: The Automatic Corrugated Box Converting Line

The Automatic Corrugated Box Converting Line is an advanced assembly of machinery designed to efficiently produce corrugated packaging solutions. This technology is vital for manufacturers looking to optimize their production capabilities while maintaining high standards of quality and consistency in their packaging processes. At the core of an automatic converting line is its ability to handle va